Case Studies

We automate mobile and stationary applications, future-proof, robust and scalable. We also offer the right diagnostics and connectivity solutions for your machines and equipment. Our systems are based on standards and a modular system. We keep the special features of customer-specific applications in mind and our systems are certified and tested accordingly.

In the following case studies you will gain a deeper insight into successfully implemented projects from our core topics, mobile and industrial automation, diagnostics and connectivity. Find out more about the tasks and challenges that we have already successfully solved with our know-how and our products.

Mobile Automation

5 inch CAN display

For a large OEM, Sontheim Industrie Elektronik GmbH has developed a CAN-based display in cooperation with the company… more

eSys-SVCx – safety control unit

Sontheim Industrie Elektronik GmbH has developed a Safety ECU family which is highly scalable and approved as a generic control unit… more

Industrial Automation

eControl micro II – with OPC UA & IO-Link

For a large machine manufacturer, the already used eControl micro was further developed to the second generation and now takes over IoT tasks…more

eControl mIO xt with OPC UA

For the German manufacturer of household and commercial appliances Miele, Sontheim has developed a touch-based control system for endurance tests that takes advantage of OPC UA… more

eControl micro and eControl nano

Sontheim Industrie Elektronik GmbH has developed the eControl family for two major OEMs in the mechanical engineering industry… more

EvoPrint® – Printing System

For a leading OEM of CNC-controlled joinery machines, Sontheim Industrie Elektronik GmbH has developed a future-proof printing system based on inkjet technology… more

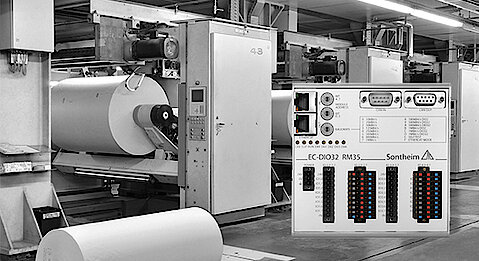

EC-DIO32 RM35 – CAN and EtherCAT IO module

We have developed a multifunctional CAN and EtherCAT module for a leading mechanical engineering company… more

Diagnostics

AEF ISOBUS checktool

A software tool for ISOBUS compatibility testing was developed and successfully implemented for the AEF Foundation… more

MDT® 2.0 – Modular diagnostic tool 2.0

In cooperation with several major mobile machinery OEMs, we have continued the success story of our MDT® (Modular Diagnostic Tool) and developed the next generation… more

Stack solutions (UDS and DOIP)

Sontheim Industrie Elektronik has developed and integrated various stack solutions for large agricultural and construction machinery manufacturers as well as for a German car manufacturer… more

Development of a diagnostic tool for the entire vehicle fleet

Based on the latest standards, we have developed a diagnostic system including a service case and VCI for a large agricultural manufacturer… more

Connectivity

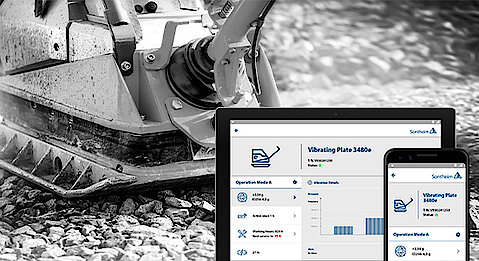

Beacon BT – Smart Bluetooth Module

Sontheim Industrie Elektronik GmbH has developed a Bluetooth module for smart networking applications in cooperation with a leading construction machinery manufacturer… more

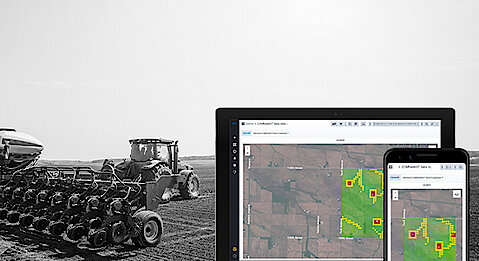

COMhawk® – Precision farming

For a leading OEM of agricultural vehicles Sontheim Industrie Elektronik GmbH has developed an IoT-Gateway for precision farming applications… more

eSys-IDC4E1 – Industrial IoT gateway

Sontheim Industrie Elektronik GmbH has developed a high-performance CAN gateway for 24/7 applications to monitor performance and detect errors in state-of-the-art placement machines… more

IoT Device Management and IoT Analytics Manager with IT integration

The cloud-based platforms IoT Device Manager and IoT Analytics Manager allow customers to manage their field devices, visualize and evaluate data… more

COMhawk® xt – University Kempten

In a research project at Kempten University of Applied Sciences, Sontheim Industrie Elektronik acted as a partner for the development of an analysis tool for fleet optimization with regard to electromobility… more